Contents

What is a Galvanometer?

Let’s start with the introduction of the New article “What is a galvanometer”.

A galvanometer is a permanent magnet moving coil (PMMC) instrument that is designed to detect and measure the small value of current and voltage in an electrical circuit.

This type of instrument is very sensitive to enormously low values of electrical quantities and is widely used for detecting and measuring the small values of current and voltage.

Galvanometers are classified into various types such as

Depending on its uses it is classified as (1) Ballistic galvanometer (2) Dead beat or periodic galvanometer.

On its nature of construction, the galvanometer is classified as (1) A Moving coil galvanometer (2) A Moving magnet galvanometer.

Based on the nature of the supply current, it is classified as (1) Dc galvanometer(D-Arsonval galvanometer) (2)Ac galvanometer(vibration galvanometer).

But the most important type of galvanometer that is used nowadays is the permanent magnet moving coil type (Dc galvanometer), which is known as the D’Arsonval type galvanometer.

Principle of Galvanometer

The galvanometer works on the principle that when a current-carrying coil is placed in a magnetic field then a magnetic torque is experienced by the current-carrying coil.

The galvanometer operates on the principle of experiencing a force on a current-carrying conductor placed in a magnetic field.

Construction of a Moving Coil Galvanometer

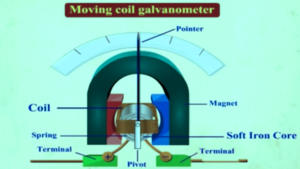

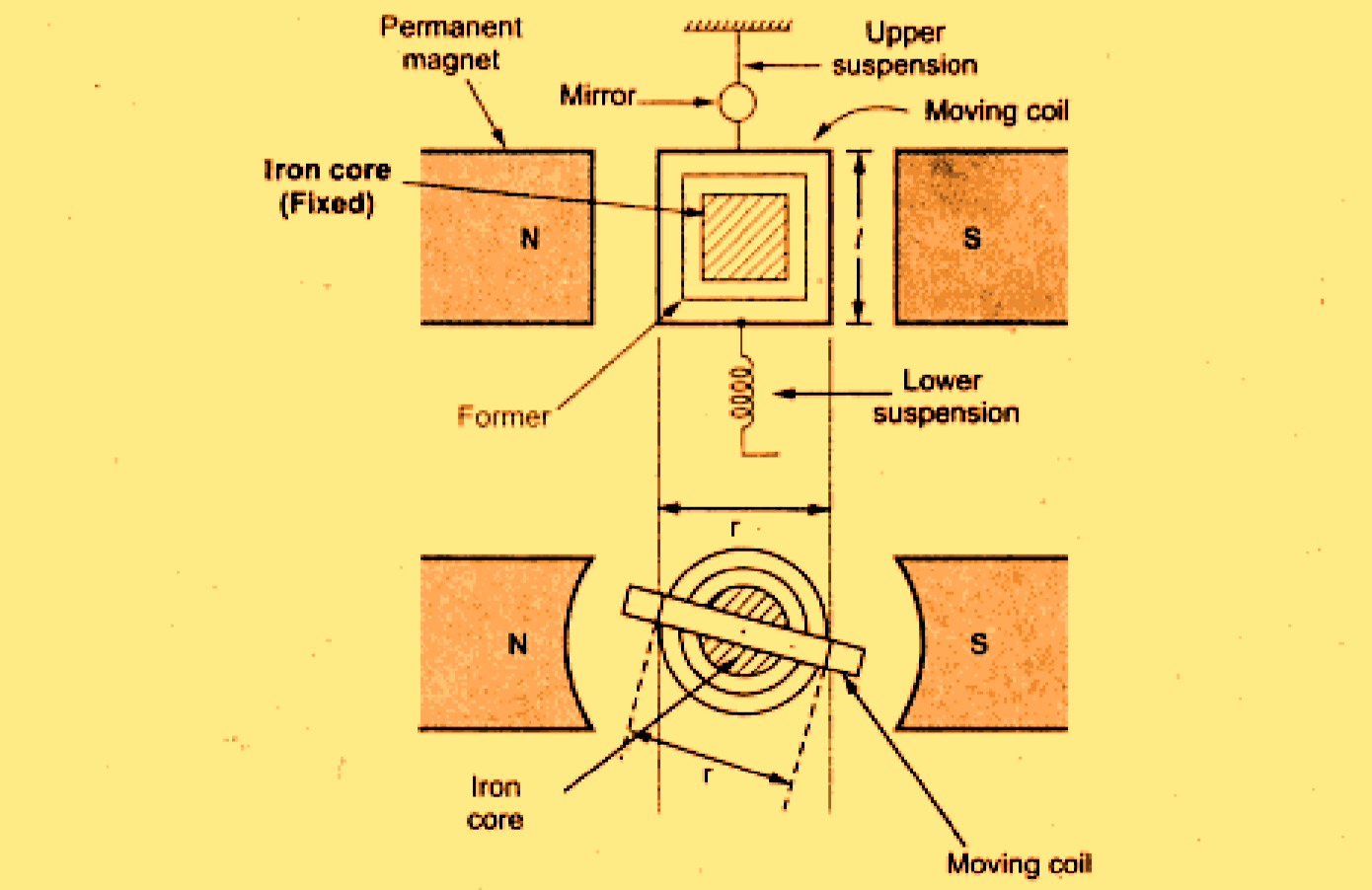

The galvanometer consists of the following parts such as strong horse-shoe magnet moving coil, Iron core, Suspension part, Damping system, Indication, Zero adjustments.

Moving coil:

The coil is suspended between the pole pieces of a strong horseshoe magnet and iron core. The moving coil present in the galvanometer is a rectangular or circular cross-section with n number of turns of very fine wire.

The moving coil carrying carries the current proportional to the quantity to be measured. The moving coil is placed in such a way that it is free to turn about its vertical axis. And the magnetic field is radial due to the horseshoe shape of the magnet.

Iron core:

The shape of the iron core depends on the shape of the coil i.e if the shape of the coil is circular then the iron core is spherical and the iron core is cylindrical if the shape of the coil is rectangular.

An iron core is used here to provide a low reluctance path to the magnetic flux and to produce a strong magnetic field. This results in higher deflecting torque and better sensitivity of the moving coil galvanometer.

Suspension system:

It consists of a single fine strip made up of phosphor-bronze and serves as one lead of the coil. The other lead takes the form of a loosely coiled spiral of the fine wire leading downward from the bottom of the coil called lower suspension.

Some type of galvanometer requires perfect leveling so that the suspension coils remain straight and in a central position without rubbing the poles of the magnet or the iron core.

Whereas some type of galvanometer which doesn’t require the perfect leveling then taut suspension with straight flat strips are used, which are kept under tension from both sides.

Damping :

The damping used in this type of system is eddy current damping. The eddy current developed in the metal former present on which the coil is mounted is responsible to produce the damping torque.

Indication:

A small mirror is attached to the suspension on which a beam of light is cast through a glass window in the instrument’s outer brass case. The beam of light is reflected on the scale. The distance of the scale is generally 1meter away from the mirror.

Zero adjustments:

For the adjustment of the coil position and its zero settings, a torsion head is provided here.

Working of a moving coil galvanometer

When a current ‘i’ flows through the coil having ‘n’ number of turns and area of cross-section is of the coil is ‘A’ is placed in uniform magnetic field ‘B’ then torque will be experienced by this coil.

Let the force on the coil will be,

F=NBiL

Where N= number of turns in the coil

A= area of the coil

B=magnetic field induction of the radial magnetic field in which the coil is suspended.

i= current in the coil.

Then the value of the deflecting torque is ‘Tdeflecting’ =NBiA

When the coil deflects a restoring torque is will be developed in the suspension fiber present.

Let ɵ be the angle of twist then the restoring torque in the suspension fiber is

‘Trestoring’=C ɵ

Where C= Torsional constant of the suspension fiber.

When the coil is in an equilibrium position or when the coil is in a steady-state position then the deflecting torque of the coil is equal to the restoring torque of the coil.

i.e, Tdeflecting =Trestoring

NBiA = Cɵ

i=C×ɵ/NBA

then, i=Kɵ

i ∝ ɵ

here ‘K’=C /NBA which is called the galvanometer constant.

Here from the above linear relationship between i and ɵ makes the moving coil galvanometer useful for measurement and detection of current.

Sensitivity of Moving coil galvanometer

A moving coil galvanometer is sensitive if the galvanometer gives larger deflection for smaller change of current through it

Let us consider i and i+di to be the value of current at initial and final conditions flowing through the coil of the galvanometer. Let ɵ and ɵ+dɵ be the deflection of the coil for the initial and final value of the current flowing through it respectively.

Thus the deflection of the coil of the moving coil galvanometer changes by an amount of dɵ when the current through it changes by an amount of di. Then the ratio of dɵ/di is called the sensitivity of the moving coil galvanometer.

Generally, four types of sensitivities are possible in a moving coil galvanometer as Current sensitivity, Voltage sensitivity, Megohm sensitivity, and ballistic sensitivity.

Current sensitivity of the Moving coil Galvanometer

The current sensitivity of a moving coil galvanometer is defined as the ratio of the deflection produced in the galvanometer to that of per unit current flowing through it.

Current sensitivity Si=ɵ/i =NBA/c

Here,B=magnetic induction

C=torsional constant

A = Area of the coil

N= number of turns in the coil

ɵ= deflection of the coil

i = current flowing through the coil

Voltage sensitivity of the Moving coil Galvanometer

The voltage sensitivity of a moving coil galvanometer is defined as the deflection produced in the galvanometer per unit voltage applied to it.

Voltage sensitivity Sv= ɵ/v =ɵ/iR (as v=iR)

And ɵ/i=current sensitivity then,

Sv = Si/R=NBA/RC

Factors affecting the sensitivity of the moving coil galvanometer

- Due to the increase in magnetic induction sensitivity of the galvanometer increases.

- As the torsional constant decreases sensitivity of the galvanometer increases.

- When the area of the coil increases then the sensitivity of the galvanometer increases.

- As the number of turns increases then the sensitivity of the galvanometer increases.

Megohm sensitivity

When the resistance required in the circuit is in mega ohm for a deflection one scale division on impressing 1v is called the megohm sensitivity.

Ballistic sensitivity

The ballistic sensitivity of a galvanometer is defined as the first maximum deflection in millimeters caused on a scale placed at a distance of 1meter from the mirror by a unit charge suddenly passed through the galvanometer.

Accuracy of Moving Coil Galvanometer

A moving coil galvanometer is said to be more accurate when the relative error in the measurement of current is less and vice-versa.

Let ‘i’ be the current flowing through the coil of the moving coil and ɵ be the deflection produced in the coil of the moving coil galvanometer and represent the actual value of the current and deflection to be measured.

Let i+di be the measured value of current and ɵ+dɵ be the measured value of deflection by using an experimenter.

Thus di and dɵ be the error present during measurement of current and deflection using the experimenter. Then this ratio is called relative error or fractional error.

Current flows through the coil of moving coil galvanometer are,

i =(C/NBA)*ɵ …….(1)

On differentiating the above equation,

di = (C/NBA)dɵ ………(2)

On dividing the equation (1) by (2) we get

di /i = dɵ/ɵ

This is the condition for the accuracy of the moving coil galvanometer.

Here di/i is called the fractional error. And if the value of fractional error is small then the moving coil galvanometer is said to be more accurate or the accuracy of the moving coil galvanometer is maximum. This is possible if the value of ɵ is large for a given value of dɵ.

Jitu Kumar is the Founder and Senior Content Head of Electrical Maker. On electricalmaker.com, we publish the latest educational updates regarding Engineering.