Contents

What is an HRC Fuse?

Introduction

A fuse is a part of the electrical circuit that consists of a conductor which melts easily and interrupts the connection of the circuit when the current in the fuse exceeds the predetermined value.

HRC (High rupturing capacity) fuse is defined as a type of fuse that can carry short circuit current safely for a given period of time.

In HRC fuse (High rupturing capacity fuse) the fuse element or the fuse wire can carry a large amount of short circuit current for a known period of time and during this time period, if the fault is removed then the fuse does not melt or blow off otherwise it melts or blows off.

This type of fuse is actually used to overcome the problems of low and uncertain breaking capacity of semi-enclosed rewireable fuses.

As in modern distribution systems, large power concentration is the main concern so it is necessary that the fuse should have a definite known high breaking capacity so it is designed to fulfill the requirement of the modern distribution system.

Normally HRC- fuses are available in the range of 2 Ampere to 800 Ampere.

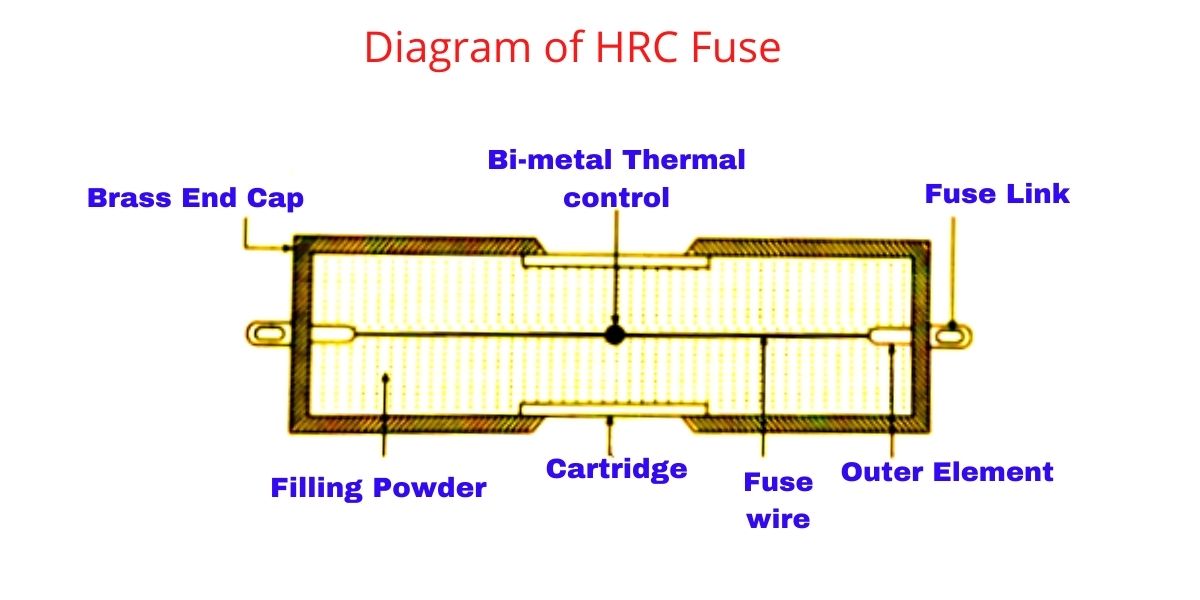

Construction of HRC Fuse

Outer Body

The outer body of a High Rupturing Capacity fuse is usually made up of a heat-resisting ceramic or porcelain body having good mechanical strength. The whole body of the HRC is fully air-tight to avoid the effect of the atmosphere on the fuse materials.

Brass end Plate

With the ceramic body, two metal end caps are attached to both heads. Usually, the metal end caps are made of copper or brass. The metal ends caps are screwed to the ceramic body by using of special forced screws to withstand the pressure developed under short- circuit condition.

Fuse Element

The fuse element or fuse wire used here is silver or copper. The fuse element is welded to the metal link contact with the help of tin joints. The tin joints are used to weld the silver fuse wire to limit the temperature of the fuse under small overload conditions.

As the melting point of pure tin (2400c) is lesser than the melting point of silver (9800c), tin prevents the silver from attaining high temperature when the circuit is overloaded.

Filling Powder

The space within the enclosure surrounding the fuse element or fuse wire is completely packed with a filling powder. The filling powder used here is generally powder of pure quartz, plaster of Paris, or Marble dust which acts as an arc extinguishing agent.

The quart powder also avoids the oxidation of silver fuse wire. The quartz powder is used as filler because it can absorb heat at a very high rate and it does not involve an appreciable amount of gas and after absorbing heat quartz powder gets converted into glass beads which restrict the path of restriking voltage.

Fuse Link Contacts

The fuse link contacts are welded to the brass or copper end caps and to these end caps fuse wire is connected as shown in the figure.

Working of HRC Fuse

Normal Condition

Let us consider the current rating of an HRC-fuse is 63 Ampere so during normal working conditions current does not exceed the current rating of the fuse as a result temperature of the fuse element does not exceed its melting point.

As a result fuse wire does not melt and the fuse continues to work normally and carries current without any interruption.

Short circuit condition

In case of overload or short circuit condition current in the circuit exceeds the rated current (63 Ampere) of the HRC fuse does not melt because the filling powder absorbs the heat produced due to increased current and the temperature of the fuse wire does not increase due to absorption of heat by filling powder.

This fuse can carry current up to 1.5 times of the rated current (here approximately 1.5 times of 63 = 94.5) under fault or overload conditions for a period of 10-12 seconds. If the current remains in the fuse for more than 10-12 second then in that condition the fuse element or fuse wire gets melted and vaporized and break the circuit.

Characteristics of HRC Fuse

It has three important characteristics which are as follow

| 1. I2t Characteristics |

| 2. Cut-off Characteristics |

| 3. Time – current characteristics |

I2t Characteristics

I2t Characteristics provide information about the heating effect due to pre- arcing current and the time of arc quenching. This I2t Characteristic provides information about the amount of energy released that is passed to the devices which are to be protected at the time of fault current interruption.

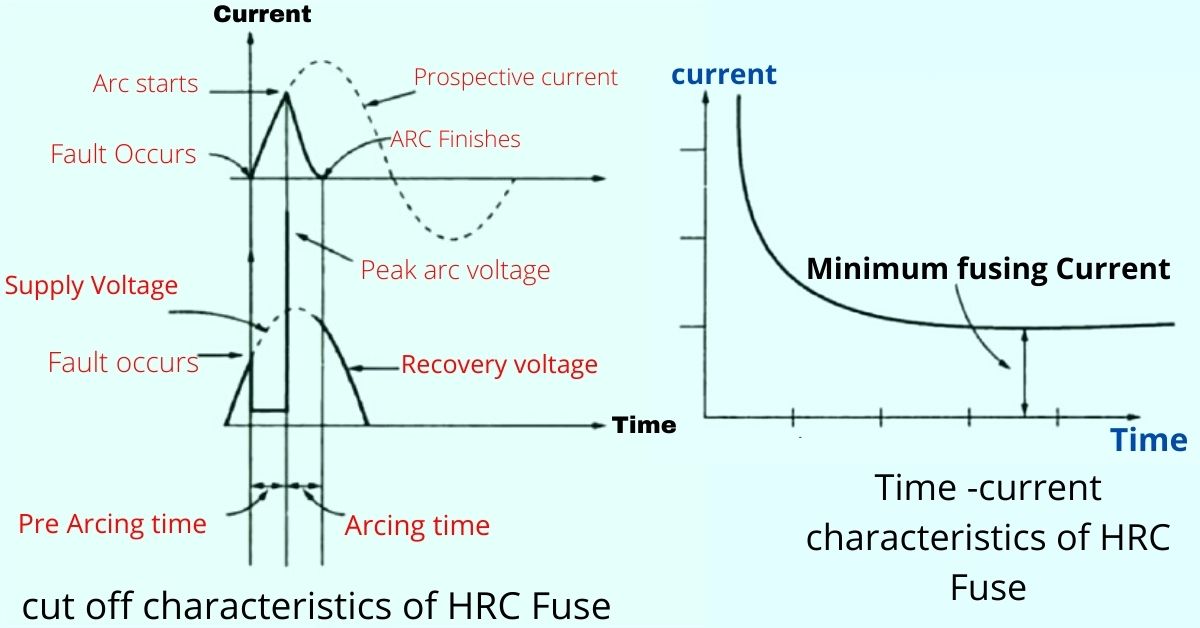

Cut-off Characteristics

The plot which shows the variation of current and voltage with respect to time just after the fault is called as cut-off characteristic of the HRC fuse.

When a fault occurs, the fault current has a large positive peak but before reaching its peak the fuse melts. This current is called prospective current.

The current at which the fuse blows and an arc starts is called cut-off current.

When a fault occurs voltage reduces momentarily and when the fuse formation melts with an arc formation then the arc voltage reaches a value that is several times more than the supply voltage.

This depends completely on the fuse length and cross-section. When the arc completely vanishes, the recovery voltage becomes normal. Here arc completely vanishes by the filling powder.

Time-current Characteristics

The plot between the fault current and the operating time in the case of the HRC fuse is called the time-current characteristics of the HRC fuse. The HRC-fuse has an inverse time-current characteristic. This means when the value of the fault current increases then the operating time of the fuse decreases.

Advantages of HRC-Fuse

|

|

|

|

|

|

|

|

|

|

|

Disadvantages of HRC-Fuse

|

|

|

|

|

Jitu Kumar is the Founder and Senior Content Head of Electrical Maker. On electricalmaker.com, we publish the latest educational updates regarding Engineering.

I read your article on the construction and working of HRC fuses. I found the article very useful. You have explained all aspects of HRC fuses in easy to understand language. Thank you.